The Rise and Impact of Chemistry Factories in Global Business

Chemistry factories play an integral role in modern manufacturing and industry. As the backbone of countless products and innovations, these establishments contribute significantly to economic growth, scientific advancement, and environmental sustainability. In this article, we delve deep into the world of chemistry factories, explore their functionalities, impact on various sectors, and the evolving landscape of chemical suppliers such as EuroChem Supplies.

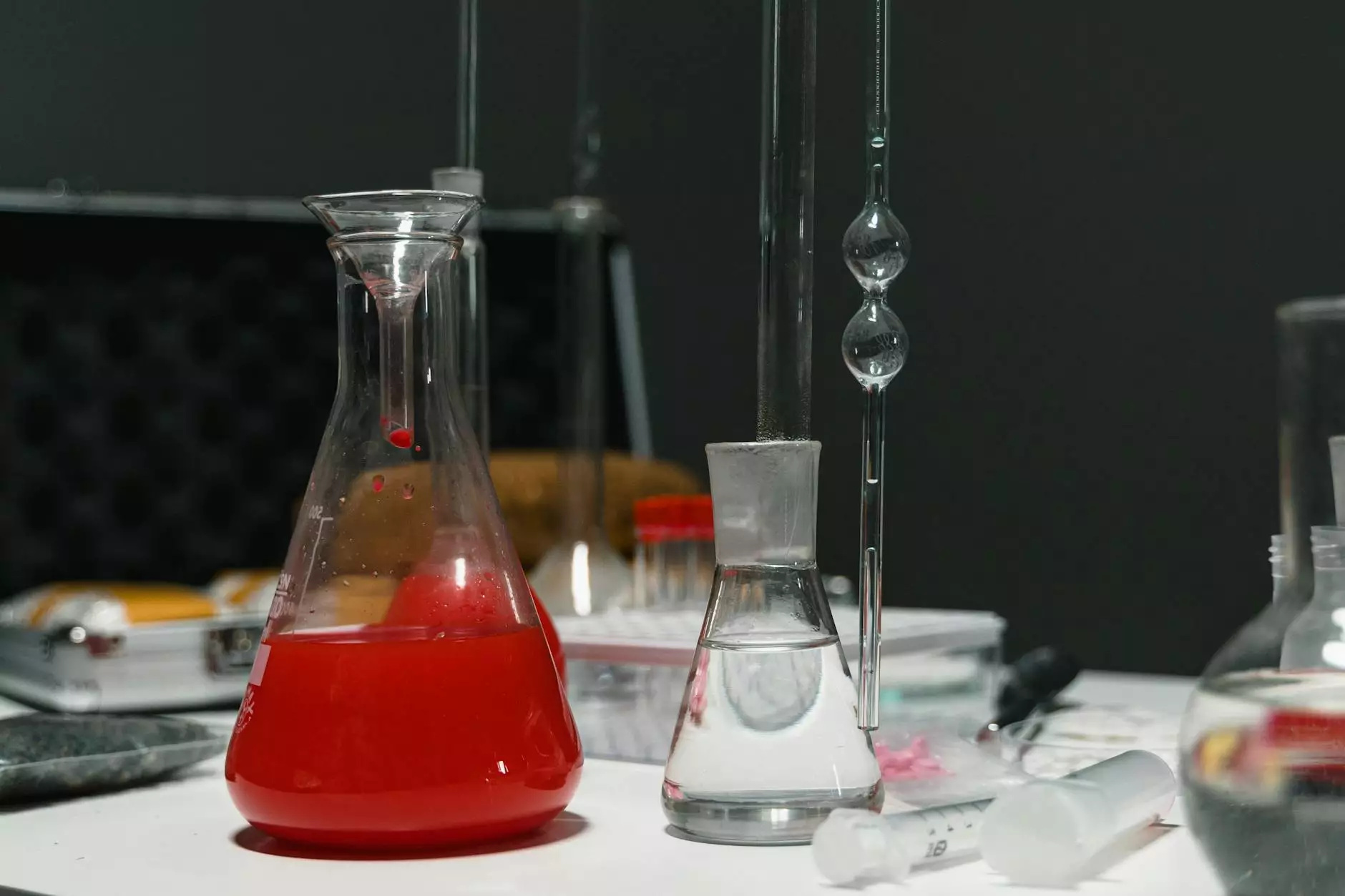

Understanding Chemistry Factories

A chemistry factory refers to a facility where chemicals are produced and processed. These factories are equipped with sophisticated machinery and technologies to ensure efficient production and high-quality output. The significance of chemistry factories transcends their manufacturing capabilities; they are crucial in fostering innovation, maintaining standards, and meeting the growing demand for chemical products.

The Role of Chemistry in Business

Chemistry is often regarded as the central science, bridging the gap between physical sciences and life sciences. In the business context, it has several applications:

- Product Development: Chemistry is essential in designing new products, from pharmaceuticals to consumer goods.

- Quality Control: Rigorous chemical analysis and testing ensure that products meet safety and efficacy standards.

- Innovation: Chemistry drives innovation by enabling the creation of new materials and technologies.

The Importance of Chemical Suppliers

Chemical suppliers like EuroChem Supplies are vital to the operation of chemistry factories. They provide raw materials, specialized chemicals, and technical expertise that enable factories to operate effectively. The relationship between suppliers and manufacturers is critical, as it influences product quality, production efficiency, and overall business success.

Key Functions of Chemical Suppliers

Chemical suppliers fulfill several pivotal roles, including:

- Raw Material Supply: Ensuring factories receive the necessary chemicals on time enhances production timelines.

- Technical Support: Suppliers often provide guidance on the usage of chemicals, safety protocols, and regulatory compliance.

- Market Insights: They offer valuable intelligence regarding market trends, pricing, and new materials.

Innovations in Chemistry Factories

As we move towards a more sustainable future, chemistry factories are undergoing significant transformations. Innovations in technology and processes are enhancing operational efficiency and reducing environmental impact. Key innovations include:

- Green Chemistry: Focused on minimizing waste and using renewable resources, green chemistry practices are reshaping production methods.

- Automation: The integration of automation and robotics increases productivity and precision while reducing human error.

- Digitalization: Implementing advanced data analytics and IoT enables better monitoring of processes and resource management.

The Impact of Sustainability on Chemistry Factories

Sustainability is a core consideration for modern chemistry factories. Companies are increasingly held accountable for their environmental impact. Sustainable practices not only help in compliance with regulations but also cater to the growing consumer demand for environmentally friendly products. Examples of sustainability initiatives include:

- Reduction of Emissions: Factories are adopting cleaner technologies to significantly lower emissions.

- Waste Minimization: Implementing recycling processes and waste-to-energy solutions.

- Resource Efficiency: Optimizing the use of raw materials to minimize depletion and maximize resource use.

Challenges Faced by Chemistry Factories

While the outlook for chemistry factories is positive, there are inherent challenges that must be addressed. These include:

- Regulatory Compliance: Strict regulations demand rigorous compliance, which can be resource-intensive.

- Supply Chain Disruptions: Global events can impact the availability and pricing of raw materials.

- Technological Adaptation: Keeping up with technological advancements requires constant investment and training.

The Future of Chemistry Factories

The future of chemistry factories looks promising as new technologies continue to emerge. The evolution of artificial intelligence and machine learning offers unprecedented improvements in predictive maintenance, quality control, and operational efficiency. As industries adapt to these changes, the demand for innovative chemical solutions will only continue to grow.

Collaboration for Innovation

In pursuit of innovation, collaboration between industry players, academic institutions, and research organizations plays a crucial role. Chemical suppliers like EuroChem Supplies can form partnerships with research entities to drive R&D initiatives that lead to groundbreaking advancements in chemical production. Such collaborations enhance the knowledge base and foster an environment where innovative ideas can flourish.

Conclusion

As we explore the intricate workings of chemistry factories and the essential role of chemical suppliers, it is clear that this sector is vital to global economic stability and growth. With ongoing innovations and a concerted effort towards sustainability, the chemistry industry stands poised to meet the challenges of tomorrow. Companies like EuroChem Supplies are at the forefront of this evolution, providing the necessary support and materials that drive the industry forward.

In an era of rapid technological advancement, the significance of chemistry in our daily lives cannot be overstated. From the products we use to the medicines we rely on, the contributions of chemistry factories are foundational to modern society. As businesses embrace these advancements, the potential for growth, innovation, and sustainability in the chemical industry is indeed bright.