The Importance of Bar Code Label Printers in Modern Business

In today's ever-evolving business landscape, the adoption of innovative technologies is crucial for maintaining a competitive edge. One such technology that has transformed the way businesses operate is the bar code label printer. These printers not only facilitate the efficient labeling of products but also play a significant role in streamlining operations across various sectors, including retail, manufacturing, and logistics. In this article, we will explore the unique benefits of bar code label printers and their importance in enhancing productivity and efficiency in business.

Understanding Bar Code Label Printers

Before delving into the benefits, it is essential to understand what bar code label printers are. These devices are specialized printers designed to produce labels that contain bar codes, which are visual representations of data. Bar codes can be scanned and read by machines, allowing for quick data input and tracking.

Types of Bar Code Label Printers

- Direct Thermal Printers: These printers use heat-sensitive media and do not require ink, making them cost-effective for short-term applications.

- Thermal Transfer Printers: These printers use a ribbon to apply ink to the label, delivering a more durable print that is resistant to smudging and fading.

- Inkjet Printers: These provide high-quality images and are versatile in printing complex designs, though they require more maintenance and supplies.

- Laser Printers: Known for their speed and efficiency, laser printers are ideal for high-volume label printing.

Each type of printer has its unique advantages depending on the specific needs of a business, including volume, label durability, and cost considerations.

Benefits of Using Bar Code Label Printers

The integration of bar code label printers into business operations offers numerous advantages:

1. Increased Efficiency

One of the primary benefits of using bar code label printers is the significant increase in operational efficiency. By automating the labeling process, businesses can dramatically reduce the time spent on manual labeling tasks. This automation leads to quicker inventory management, expedited shipping processes, and enhanced order accuracy. Employees can focus on more critical tasks rather than spending hours manually labeling products.

2. Enhanced Accuracy and Reduced Errors

Human errors in data entry can result in inventory discrepancies, leading to costly mistakes. Bar code label printers minimize these errors by providing a machine-readable format that ensures correct data input. Scanning bar codes reduces the likelihood of misplaced items and inaccurate stock levels, ultimately leading to improved inventory accuracy.

3. Streamlined Inventory Management

Effective inventory management is vital for any business. The use of bar code label printers allows companies to track inventory levels in real time. By integrating bar code systems with inventory management software, businesses can monitor stock levels, manage reorder processes, and analyze sales trends effortlessly. This capability empowers businesses to make data-driven decisions that optimize their inventory practices.

4. Improved Customer Satisfaction

Customer satisfaction is paramount in any business. By ensuring accurate inventory levels and speedy order fulfillment through the use of bar code label printers, businesses can enhance their service offerings. Accurate labeling helps prevent stockouts, enabling customers to receive their desired products without delay. Additionally, the clear and professional appearance of bar codes can enhance the customer experience.

5. Cost Savings

Investing in bar code label printers can lead to significant cost savings in the long run. Although there may be upfront costs associated with purchasing printers and labels, the efficiency gained often outweighs these expenses. Reduced labor costs, fewer errors, and improved inventory management can result in substantial savings over time.

6. Versatile Applications Across Industries

Bar code label printers are not confined to one industry; they find applications across various sectors, including:

- Retail: For product labeling, price tags, and promotional labels.

- Manufacturing: For tracking raw materials, finished goods, and assembly line processes.

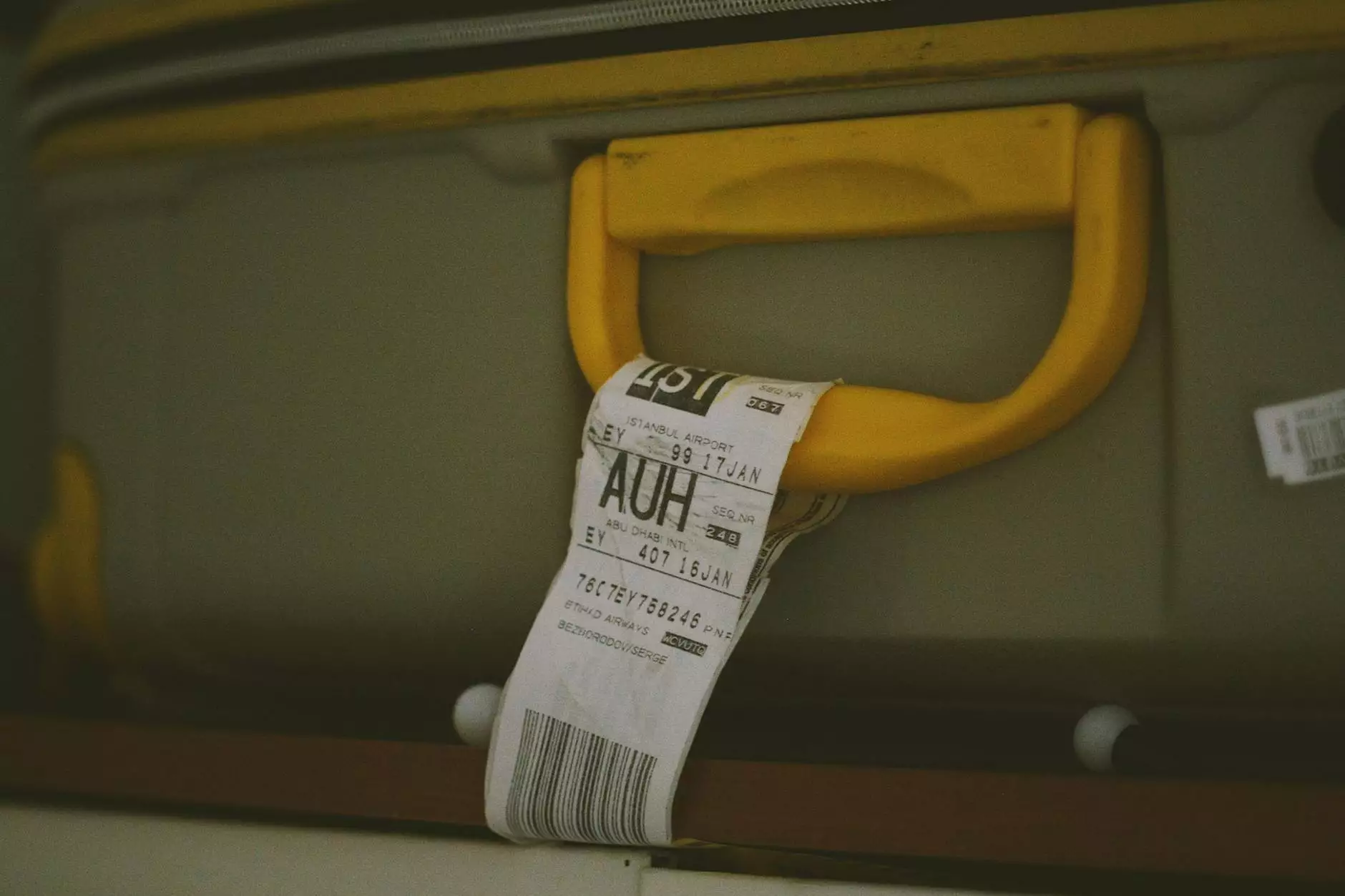

- Logistics: For shipping labels and parcel tracking.

- Healthcare: For labeling medications, laboratory samples, and patient identification.

- Food and Beverage: For labeling ingredients, expiry dates, and product information.

How to Choose the Right Bar Code Label Printer

Selecting the right bar code label printer for your business needs requires careful consideration of several factors:

1. Identify Your Printing Needs

Consider the volume of labels you need to print, the type of labels required (size, color, material), and the required durability of the labels. Understanding your specific needs will guide you in selecting the most suitable printer.

2. Evaluate Your Budget

Determine your budget for the printer and any ongoing costs for supplies like ink, labels, and maintenance. Balance the initial investment with the long-term benefits and savings you expect to receive.

3. Consider Software Compatibility

Ensure that the bar code label printer you choose is compatible with your existing software systems. This compatibility is crucial for seamless integration and efficient operations.

4. Research Printer Performance and Reliability

Look for reviews and testimonials from other businesses regarding the performance and reliability of the printer. A printer that frequently breaks down or has software issues can lead to costly interruptions in operations.

5. Assess After-Sales Support

Consider the manufacturer's support options. Having reliable technical support can save you time and resources in the event of issues or technical difficulties.

Real-World Success Stories of Bar Code Label Printers

Many businesses have successfully implemented bar code label printers into their operations, reaping the benefits of increased efficiency and improved accuracy. Here are a couple of case studies:

Case Study: A Retail Giant's Transformation

A large retail chain implemented bar code label printers to modernize its inventory management processes. The results were remarkable:

- Reduced time spent on inventory counts by 60%.

- Decreased product mislabeling incidents by 75%.

- Improved overall customer satisfaction ratings by 20%.

Case Study: Streamlining Logistics Operations

A logistics company adopted bar code label printers to track shipments more effectively. The impact was profound:

- Increased shipment tracking accuracy to 99%.

- Reduced order processing time by 50%.

- Enhanced clarity in communication with clients about shipment statuses.

Conclusion

In summary, bar code label printers are essential tools that can transform business operations. By enhancing efficiency, accuracy, and customer satisfaction, these printers are invaluable in today's competitive market. Whether you are in retail, manufacturing, logistics, or healthcare, investing in bar code label printers will position your business for success. Embracing this technology will not only streamline your labeling processes but also contribute to long-term profitability and growth.

Investing in quality bar code label printers from reliable suppliers such as OmegaBrand ensures that your business reaps the maximum benefits from this technology. Explore the various options available and take the first step towards revolutionizing your business operations today!